Backwashing a drinking water system filter means reversing and increasing the water’s flow to flush out accumulated debris and particles. Backwashing is not only vital to the life of a filter but also is essential to maintain the quality of water coming out of the filter. Depending upon the incoming water quality, age and type of filter media all filters need to be backwashed or replaced. The turbidity of water (cloudiness or haziness caused by a large number of particles) coming out of the filter (filter effluent) is a good indicator to determine backwash frequency and duration. Head loss on the filter also indicates the need to backwash. Head loss is usually measured with a negative pressure gauge.

Backwashing water filters are large tank-style filters that clean and renew themselves by the process of backwashing. The filter bed itself is a granular substance that is usually referred to as the filter medium. Common types of filter media are granular carbon, sand, anthracite, zeolite, granular manganese dioxide, and greensand. This article discusses the automatic backwash filter systems for commercial point-of-entry applications manufactured by the leading water filtration company – 3M.

Product Description & Features

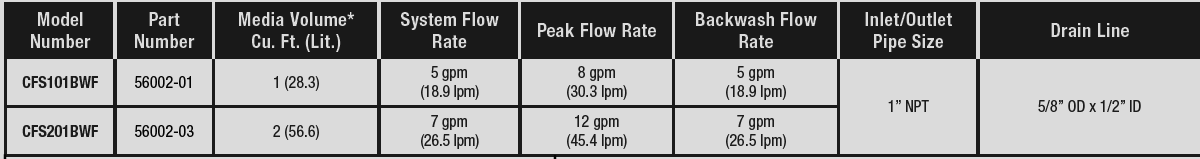

The 3M™ Water Filtration Products CFS101BWF and CFS201BWF automatic backwash systems allow for the reduction of bulk sediment at the point-of-entry applications. This means that it treats water as it enters the building. Coarse filtration down to 20 micron captures particles and can help extend the life of finer filtration downstream. Choices of other media can address site specific water conditions. Table below summarizes the media volume, peak flow rate, system flow rate, and backwash flow rate for the two models.

The product features for the two models are listed below:

- Control valve is designed for reliable service.

- Full flow bypass for ease of service and maintenance.

- Time clock initiation allows a backwash cycle to take place during non-peak demand.

- Choice of media for differing water quality conditions as shown below

Backwashing filters have the following two main stages of operation:

- Filtration Stage

The medium flows through the filter element either from inside to outside or from outside to inside. Here the dirt particles are retained and the cleaned medium reaches the filter outlet. When the differential pressure reaches a certain value, a signal is transmitted from the differential pressure indicator to the control unit, which automatically triggers the backwashing process. - Backwashing Stage

When the differential pressure reaches a certain value, the differential pressure indicator transmits a signal to the control system, which automatically triggers the backwashing process. During backflushing, the dirt particles are flushed off of the filtration surface by filtered fluid reversal of flow (own medium or through external flush medium, compressed air or service water).

3M has been offering applied innovation and technology to improve customers’ lives and support their businesses since the past 100 years. The automatic backwash filters provide a varied number of advantages especially when treating large volumes of drinking water to be used for commercial applications such as restaurants, beverage industry, etc.

![]() is one of the exclusive suppliers and consultants for PENTAIR/EVERPURE Water Filtration Products. The consultants at Sani Water can help their customers with suitable recommendations for organic matter removal and to resolve taste and odor issues. The technicians can also help with installation of the recommended filter products. SaniWater is dedicated to offer best solutions to meet the drinking water requirements of their customers.

is one of the exclusive suppliers and consultants for PENTAIR/EVERPURE Water Filtration Products. The consultants at Sani Water can help their customers with suitable recommendations for organic matter removal and to resolve taste and odor issues. The technicians can also help with installation of the recommended filter products. SaniWater is dedicated to offer best solutions to meet the drinking water requirements of their customers.